What’s Actually Inspiring Manufacturing in Outer Space?

Launching the Space Economy

The Space Age dates back to the 1950s and was primarily funded by the Soviet Union and United States governments. The two rivals raced to launch objects into space to demonstrate national superiority in technology. This led to dramatic advances in many fields ranging from materials science to microelectronics and humans walking the moon. But, as the national rivalry dissipated in the late 20th century alongside a series of human spaceflight disasters, fascination with space began to wane. Flash forward to today and new financial opportunities for outer space exploration and private spaceflight have galvanized a new Space Economy.

Private spaceflight got a jolt in 2004 by the late Paul Allen, a co-founder of Microsoft, when his SpaceShipOne claimed the Ansari X-Prize. The $10 million dollar prize was awarded for achieving the first privately funded human spaceflight capable of carrying three passengers to 100 km.

Since then, many now billionaires including Elon Musk, Jeff Bezos, and Richard Branson have built companies that seek to shape the Space Economy for years to come. Musk’s SpaceX has led the way by orbiting a reusable rocket, launching a satellite internet constellation, and developing an interplanetary spaceflight system. Jeff Bezos’s Blue Origin is also making “partially and fully reusable launch vehicles that are safe, low cost and serve the needs of all civil, commercial and defense customers.” While Richard Branson’s Virgin Galactic is focusing on suborbital spaceflights for space tourists. These pioneers of launch technology have opened the doors for aspiring start-ups to build factories in outer space.

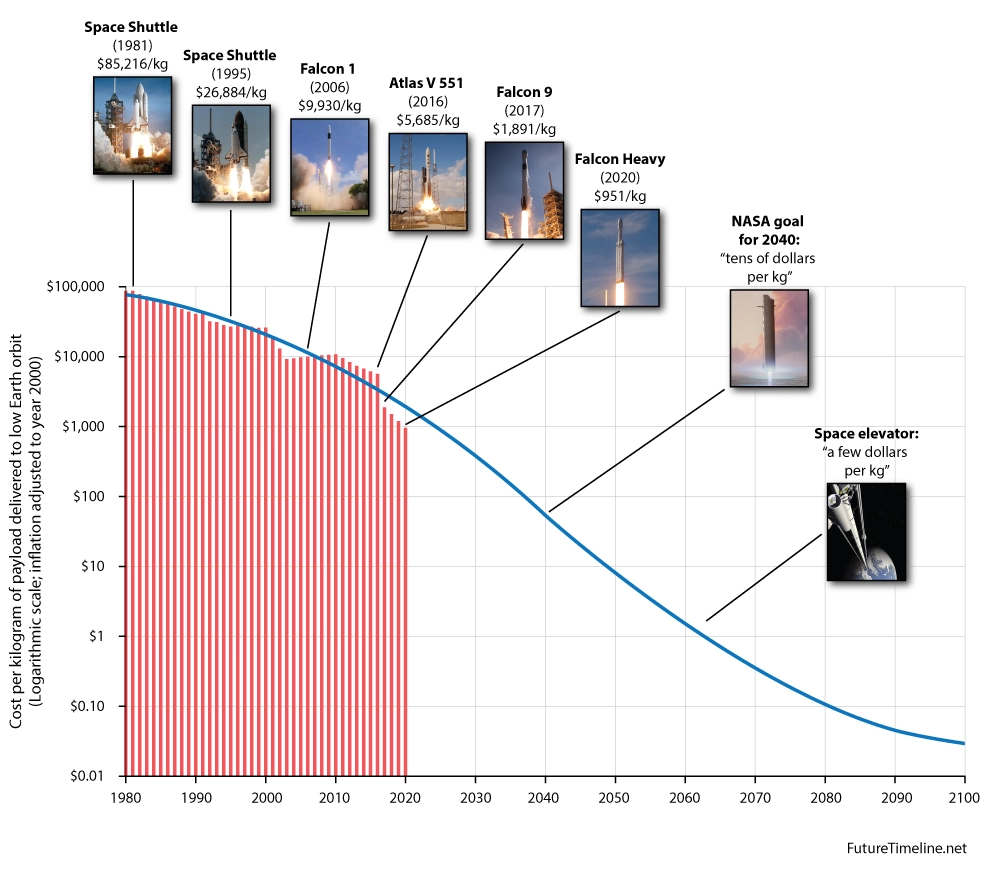

Exponential cost per kilogram declines for space launches has enabled space manufacturing startups.

However, a few prohibitive factors have long complicated the economics of the space industry: launch cost, technical expertise, and availability of capital. The combination of improvements in engine and propulsion design alongside new rocket fabrication techniques continue to significantly reduce rocket launch costs year over year (see the image above). Also, the technical expertise from the pioneering companies combined with leading universities have created a critical mass of skilled engineers and scientists that are able to collaborate with simulation tools and information systems to rapidly assess the feasibility of new Space Economy ideas. With these two critical factors addressed, the last need for space manufacturing startups is capital. Due to unique circumstances that are beyond the scope of this post, venture capital has been readily available for this new generation of space manufacturing startups.

The Startups Making Outer Space A Manufacturing Hub

Similar to the trajectory of launch objectives, in-space manufacturing plans originate within governmental space agencies but do not end there. NASA’s plans discuss building an additive manufacturing facility and performing multi-material fabrication with printed electronics. While recent a European Union funded project, PULSAR, seeks to “construct in orbit the primary mirror of a telescope from separate parts.” These worthy missions primarily seek to build and consume products in outer space to advance governmental goals. On the other hand, private enterprises have begun to push the boundaries to manufacture in space for use in terrestrial applications including zany ideas like dropping artificial human organs from space. A number of startups have made traction towards more tractable goals which will be detailed below.

Space Tango

Space Tango’s mission is to manufacture health and technology products in space that create value and transformational solutions. As a leader in automated systems, Space Tango pursues pathways to on-orbit production. Our vision is to inspire, innovate and create a better future for humanity by utilizing the environment of space.

Space Tango founded in 2014, was among the first companies to try manufacturing in space. Through its partnership with the International Space Station (ISS), “Space Tango streamlines the process of conducting experiments in the unique environment that microgravity offers.” Its ISS TangoLab facilities offer “autonomous, configurable ecosystems designed for microgravity research and small-scale manufacturing.” Additionally, Space Tango has developed its own re-entry free-flying orbital platform, ST-42, which uses “microgravity to manufacture health and technology products.”

GITAI

GITAI is a space robotics startup that will develop robots that can conduct tasks in all realms of space development, and cut down costs for operations by the Moon and Mars and construct space colonies.

GITAI established in 2016 also started on the International Space Station with an autonomous robot arm. Its robot was able to “succeed in executing two tasks: assembling structures and panels for In-Space Assembly (ISA), and operating switches & cables for Intra-Vehicular Activity (IVA).” They seek by 2040 to “be an equal partner with the world’s leading space launch companies, providing cheap and safe labor to build cities and space colonies on the moon and Mars.”

Varda Space Industries

Varda Space Industries is building the world’s first commercial zero-gravity industrial park at scale. Reusable rockets have lowered the cost of access to space and opened up a range of in-space activities. From more powerful fiber optic cables to new, life-saving pharmaceuticals, there is a world of products used on Earth today that can only be manufactured in space. Varda is accelerating innovation in the space industry and creating products that will benefit life on Earth. Our mission is to expand the economic bounds of humankind.

Varda Space Industries emerged in late-2021 after a couple years in stealth. According to TechCrunch, “Varda separates itself [from Space Tango and others] by its loftier ambition — to manufacture commercially viable products at scale in space.” They seek to manufacture products with high dollar per-unit-mass value that can be transported back to Earth. But that’s not all, Varda hopes to “build the first infrastructure that can harvest source materials for new products in-space via asteroid mining.”

The Rest of The Stars

Launch Services

- Rocket Lab (NASDAQ: RKLB), incorporated 2006 - “Rocket Lab is an end-to-end space company delivering reliable launch services, spacecraft, satellite components, and on-orbit management.”

- Relativity Space, 2015 - “As a vertically integrated technology platform, Relativity is at the forefront of an inevitable shift toward software-defined manufacturing. By fusing 3D printing, artificial intelligence, and autonomous robotics, we are pioneering the factory of the future. Leading an unrivaled team to solve problems never solved before, our leadership includes seasoned veterans and experts from the world’s most renowned aerospace, 3D printing, and technology companies. Together, we are revolutionizing how rockets are built and flown.”

- Astra (NASDAQ: ASTR), 2016 - “Today, Astra offers one of the lowest cost-per-launch dedicated orbital launch service of any operational launch provider in the world. Astra delivered its first commercial payload into Earth orbit in 2021, making it the fastest company in history to reach this milestone, just five years after it was founded in 2016. Astra was the first space launch company to be publicly traded on Nasdaq.”

- Launcher, 2017 - “Launcher is the only company with dedicated launch + orbital transfer or rideshare. Our orbital transfer vehicle and satellite platform compatible with SpaceX Rideshare and Launcher’s small launch vehicle.”

Space Economy

- Redwire (NYSE: RDW), 2020 - “Decades of flight heritage and innovation of world-class technologies combined with our mission success and focus on customer satisfaction have positioned Redwire Space as a leader in advancing the future of space infrastructure. Redwire’s operating units are organized into broad business areas focusing on space commercialization, digitally engineered spacecraft, on-orbit servicing, assembly, and manufacturing, advanced sensors and components, and space domain awareness and resiliency.”

- Sierra Space, 2021 - “Sierra Space is building a shared ecosystem in space for scientific collaboration and innovation to enhance life on earth. With technologies that make space more affordable and accessible, we’re dedicated to creating a prosperous and secure space economy that will benefit all of humanity. Rapidly advancing toward the launch of the next generation of space transportation, the world’s only winged commercial spaceplane, the Dream Chaser, will perform cargo supply and return missions for NASA, set to begin in 2023 - delivering up to 12,000 pounds of cargo to the International Space Station at a time. Sierra Space is also the developer of the Large Integrated Flexible Environment (LIFETM) Habitat, a modular, three-story commercial habitation and science platform. The unique structure will provide opportunities for multiple businesses including manufacturing, pharmaceuticals, and other sectors, to optimize zero gravity benefits. The Dream Chaser Spaceplane and LIFE platform are central components of the joint partnership Orbital Reef commercial space station and mixed-use business park being developed in partnership with Blue Origin.”

Terrestrial Companies

Back on Earth, traditional companies are also targeting the emerging space economy. STMicroelectronics has developed radiation hardened integrated circuits fit for use on next generation satellites. Additive manufacturing companies, like Velo3D and Desktop Metal, are driving the new rocket fabrication and repair techniques mentioned earlier.